In the field of manufacturing and packaging, die - cutting machines play a crucial role in shaping various materials into desired forms. Two common types are flatbed die - cutting machines and rotary die - cutting machines, each with distinct characteristics that make them suitable for different applications.The two machines differ mainly in production volume, material type, precision requirements and budget.

KISS-330SD High-speed Flatbed Die Cutting Machine

Flatbed Die Cutting Machine: The platen and pressure mechanism of the flatbed die cutting machine are both flat. It includes vertical and horizontal types1. The vertical one has a simple structure, and the platen moves around a fixed hinge or swings on a flat guide rail and then moves horizontally to press the die-cutting plate1. The horizontal one has a horizontal platen and pressure plate, and the pressure plate is driven by a mechanism to press upward against the platen1.

Rotary Die Cutting Machine: Both the plate cylinder and the pressure mechanism of the rotary die cutting machine are cylindrical1. It consists of a die-cutting plate cylinder and a pressure cylinder1.

Flatbed Die Cutting Machine: The material is placed on the flat base, and the steel rule die on the movable platen moves vertically to cut the material on the sheet or roll.

Rotary Die Cutting Machine: The material is fed between the die cylinder and the anvil cylinder continuously. The cutting edge of the die pinches the material against the anvil cylinder to make clean cuts or perforations.

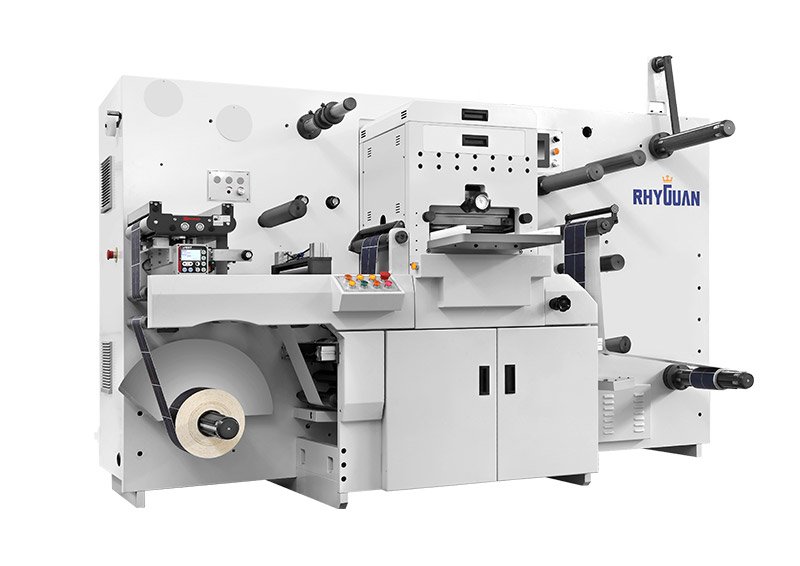

TOP-330-3 Fast Multi-Functional Label Die Cutting Machine

Production Efficiency:

Flatbed Die Cutting Machine: The production speed is relatively slow, usually suitable for small-batch production1.

Rotary Die Cutting Machine: With continuous rotation, it has a high production efficiency and is suitable for high-volume production1.

Cutting Precision:

Flatbed Die Cutting Machine: The precision is relatively lower. It is difficult to achieve high-precision cutting for some complex shapes and fine patterns.

Rotary Die Cutting Machine: It has a high level of precision and can control the relative runout between the plate cylinder and the impression cylinder within a small range.

Kiss Cutting Capability:

Flatbed Die Cutting Machine: It generally cannot perform kiss cutting.

Rotary Die Cutting Machine: It can perform kiss cutting, which is very important for producing stickers, labels and decals.

Flatbed Die Cutting Machine: It can cut thicker materials and materials in sheet form.

Rotary Die Cutting Machine: It is suitable for thin materials that can be fed continuously in roll form.

Flatbed Die Cutting Machine: The tooling development is fast and simple, and the equipment and die costs are relatively low, which is more cost-effective for small-batch orders.

Rotary Die Cutting Machine: The die manufacturing cost is high. But when the production volume is large, the unit cost can be reduced.

In conclusion, the choice between a Flatbed Die Cutting Machine and a Rotary Die Cutting Machine depends on various factors such as production volume, material type, precision requirements, and budget. Manufacturers need to carefully evaluate these factors to select the most suitable die - cutting solution for their specific needs.

● Another PLUS-330 Machine Installed in Latin America

● Another Two Installations at Customers’ Site

● Rhyguan Plus Month

● Top security level in Rhyguan

● Another Rotary Die-cutting Installation at Cutsomer’s Site

● Perfect Factory Acceptance Testing for Label Inspection Machines

● New Rhyguan Factory Preview

● Rhyguan Industrial 4.0 Live Presentation

GET A QUOTE