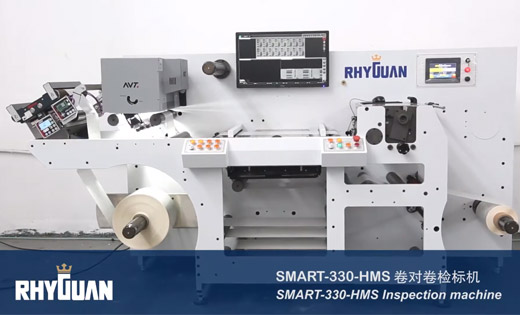

Advanced offline inspection solution. The SMART-330HMS optical camera recognises and records all defects, the PrintFlow Manager system works with the rewinder to remove the defects, and the Automatic Identification System (AIS) supports the defect inspection on-demand, and handles the final report editing.

Servo-driven, full rotary die cutting machine for blank labels, complete with a slitter and turret rewinder. High accuracy converting in speeds of up to 120 m/min.

Machine with coating units, offering excellent top coatings, primers, and adhesives for film and paper applications. Reverse printing on transparent materials. 6 meters or more drying length, with machine speeds up to 120 m/min.